Basics of machine guarding

Machines provide a vital function with their ability to perform repetitive tasks at high speeds and to apply extreme forces to shape, cut, bend, lift and move materials. These attributes can increase production, quality, and business profits; unfortunately, they can also be the source of severe, life-altering injuries or fatalities when machines are not properly designed and safeguarded.

Ideally, worker exposure to machinery hazards should be eliminated or reduced by design to a safe level. When this is not possible, then machine guarding is required1 to prevent accidental and intentional access to injury-causing hazards. Effective machine guarding protects workers who are at the point of operation where work is done, who are involved in machinery operations, and those in the machine work area.

Most machinery today comes with some level of guarding provided by the manufacturer, but this does not ensure it complies with current regulatory or consensus standards. Similarly, there is no exception allowed for lack of proper guarding on older equipment relative to an employer’s safety obligations. In short, manufacturer-installed guards do not replace an employer’s responsibility for providing a safe workplace and protecting employees from recognized hazards.

Whether new, used, modified or original, it is the employer’s responsibility to ensure that all machinery used by employees is safe for operation.

3 Steps to Effective Machine Guarding for Mechanical Hazards

- Determine Risk Factors

- Identify Guarding Priorities and Control Options

- Evaluate and Maintain Safeguards

1. Determine risk factors

Whenever possible, read and understand the equipment manufacturer’s operations and user manuals. As the end-user you must identify and understand the potential risk factors. One way to do this is to conduct a machine risk assessment using Nationwide’s sample form. This form allows for documenting the risk assessment and provides guidance on identifying risk levels.

Ideally, an assessment should be done as part of the installation of machinery and whenever modifications to the machinery are made. This can also be done as part of a Job Hazard Analysis. A good assessment of potential risk factors should include consideration of all aspects of the machine’s operations and those who may be in the area of operations.

2. Identify guarding priorities and control options

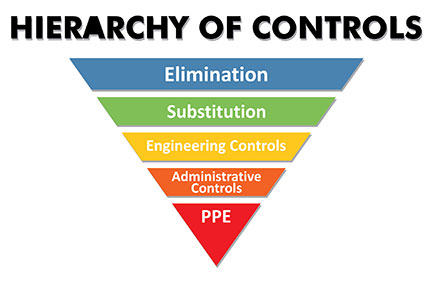

Once the initial risk assessment is completed, identify your guarding priorities and determine the best control options. Safeguarding priorities should follow the Hierarchy of Controls concept.

When possible, machinery hazards should be eliminated, substituted, or reduced by engineering controls to a safe level. This may be possible by using full or partial automation, making a process change such as increasing clearances to eliminate pinch points, or updating to safer equipment components. After this is done, safeguarding mechanisms must be used to protect against the remaining hazards. This can be a combination of barrier guards, devices and methods.

A critical part of the guarding selection and design process is to involve all stakeholders who will be involved. Operators, maintenance, housekeeping, supervisors and upper management should all be involved in the process to ensure the guarding solution follows the general principles of guarding.

General principles for mechanical hazard guards

To be effective, machine guards should be constructed of materials capable of withstanding workplace conditions and expected forces. They should be designed in such a way as to:

- Prevent Contact — The guard should eliminate the possibility of any part of a worker’s body coming into contact with dangerous moving or otherwise hazardous parts. Workplace rules guiding safe work-practices should prohibit loose clothing, dangling hair, jewelry, or other exposures that could lead to pulled-into injuries.

- Be Secure — Guards should be secured in a fashion such that operators are unable to remove or tamper with them, and substantial enough to withstand the conditions of normal use.

- Protect from Falling Objects — The guard’s design should eliminate the chance of objects, such as tools or materials, from falling into moving parts.

- Create No New Hazards — A safeguard should not introduce any new hazards, such as sharp or jagged edges that could cause a laceration.

- Not Interfere — Guards that get in the way of a worker performing the job efficiently and comfortably are likely to be removed or overridden. Consult with workers when designing guards to identify any potential interference or with operations.

- Allow safe lubrication — Machine lubrication should be possible without removing guards.

When evaluating or developing guards, the acronym AUTO can help you to ensure that the guard prevents a person from being able to access the hazard area by going Around, Under, Through or Over a guard.

3. Evaluate and maintain safeguards

Once effective safeguarding measures have been determined and implemented, Nationwide’s sample assessment tool provides for a recalculation of the risk level. However, it is important to ensure that the safeguards provided function as intended and remain in working order. This is done by conducting routine inspections of the guarding mechanisms and observations of work practices. Close observation should be made for any signs of tampering or bypassing guards.

As with the development of the guarding solution, it is critical that this part of the process includes feedback from all employees involved with using the machinery. Tampering or bypassing may be the result of guards interfering with job performance and employee feedback may lead to a better guarding solution.

Re-evaluations should be conducted whenever there is a machinery change or process revision to ensure it does not interfere with existing guarding or create additional hazards.