Waste oil heating safety

Waste oil heaters provide a primary or secondary heat source for many businesses, but these systems should be controlled because they may cause some risks.

In a time when oil prices are volatile and people have become more environmentally conscious, much attention has been focused on the use of alternative fuels.

Waste oil heaters provide a primary or secondary heat source for many garages, repair shops and wareho¬-uses. However, waste oil heating systems should be closely controlled because they burn an inconsistent fuel, which may cause some risks. To minimize these risks, all waste oil heaters should be installed by a licensed professional according to federal, state and local codes. These heaters should be cleaned, maintained and serviced at regular intervals.

Here are some commonsense measures to reduce the risks arising from the use of waste oil heaters in commercial buildings.

Before purchasing your waste oil heater:

- Verify the unit is certified by a nationally recognized testing organization, such as UL (Underwriters Laboratories). In the United States, the UL Certification Mark is required by federal, state and local building codes, as well as the National Fire Protection Association (NFPA).

- Ensure the unit has an external air compressor whenever possible — because it’s more reliable, provides cleaner burning and produces less ash.

- Require a unit with safety controls such as combustion sensors, flame failure devices, thermostatic controls, high temperature limit switches and remote emergency shutoff switches.

- Confirm the unit is equipped with self-igniting or electric spark-ignited burners to eliminate the safety hazards associated with hand-lit units.

After purchasing your waste oil heater:

- Locate the unit in an occupied building only — in an area convenient for service and free of combustible materials like wood, cardboard, paper or flammable liquids.

- Install the unit according to the manufacturer’s instructions regarding clearances to combustible materials, electrical wiring and fuel storage procedures.

- Ensure all electrical connections are “solid-wired” as outlined by the manufacturer — and not of the “plugged-in” variety. All electrical connections must meet electrical code requirements.

- Follow all manufacturer’s guidelines for safe operation.

- Only personnel that are trained to use the waste oil heater should operate the unit.

- Filter oil before placing it in the unit’s storage tank, as it will run cleaner and require less maintenance.

- Label all waste oil storage tanks: “Used Oil Only,” as per NFPA requirements.

Maintaining your waste oil heater

Ongoing maintenance of a waste oil heater should be performed at recommended intervals as outlined in the owner’s manual. If not specifically provided by the manufacturer, use the following practices:

- Inspect and clean the heater and chimney flue pipe before each heating season.

- Clean the ash from your heater and chimney flue pipe at least twice during the heating season (after every 700 hours of operation).

- Never allow more than 1/4" of ash to accumulate in the combustion chamber, heat exchanger, flues or stack. (As ash accumulates, furnace heat output declines and the chimney flue pipe temperature rises — resulting in inefficient and potentially dangerous operation.)

- Be aware that used oils may contain heavy metallic compounds or foreign materials. When burned, these compounds are deposited within the heater and will require additional cleaning.

- Use protective gear when cleaning the heater or chimney flue pipe — including a respirator designed for use with fine particles, rubber gloves, safety goggles and protective clothing.

- Never use waste oil fuel contaminated with gasoline or other flammable liquids. Dispose of it properly.

Chimney or flue pipe considerations

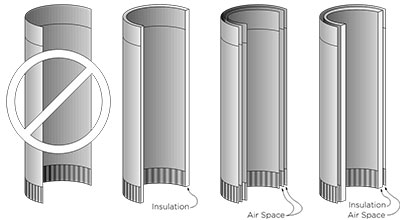

Most manufacturers of waste oil heaters specify requirements for the type of chimney flue pipe required. Local building codes may require additional protections related to the proper exhaust ventilation of commercial heating appliances. Be sure to follow all applicable requirements and ordinances when installing a chimney flue pipe to your waste oil heater. Chimney flue pipes commonly used with waste oil heaters can be manufactured from metal, galvanized steel or stainless steel. The three common types of metal chimney flue pipe are single-wall, double-wall and triple-wall. (See “Chimney flue pipe types” illustration below)

If not specifically outlined by the manufacturer or local building codes, consider the following in selecting a chimney flue pipe:

- A triple-wall flue pipe is preferred over a double-wall pipe.

- Single-wall pipe should not be used unless specified by the equipment manufacturer, and if used it should have a minimum 24-gauge thickness.

- Stainless steel flue pipe is preferred over galvanized steel pipe. Metal pipe should not be used unless specified by the equipment manufacturer.

- Class A-rated chimney pipe that meets either the UL 103 or UL 103HT Standard is required by federal, state and local building codes, as well as the NFPA. (Note: The UL 103 Standard requires that a chimney pipe is capable of safely operating with an internal temperature of 1,000 F and withstanding a maximum temperature of 1,700 F. The comparable numbers for the UL 103HT standard are 1,700 and 2,100 degrees.)

Safety standards that apply to waste oil heaters

Applicable safety standards for waste oil heaters published by the NFPA include: NFPA 211, Standard for Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances, and NFPA 31, Standard for the Installation of Oil-Burning Equipment. UL addresses these units in its publication titled UL 296A, Standard for Waste Oil-Burning Air-Heating Appliances.

Please note that the information in this brochure may not address all hazardous conditions at your location and does not warrant workplace safety or compliance with federal, state or local laws.